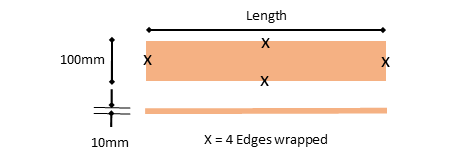

2000mm length x 100mm high x 10mm depth Copper Upstands

2000mm length x 100mm high x 10mm depth Copper Upstands.

Our standard copper upstands are manufactured from a 0.9mm thick grade C106 H/H material. They are designed with a moisture resistant MDF core and can be easily fixed and sealed to a wall using silicone adhesive or similar. They come finished and wrapped over on all edges, the corners are not welded but can be for a small additional charge.

- Specification

Our standard copper upstands are manufactured from a 0.9mm thick grade C106 H/H material. They are designed with a moisture resistant MDF core and can be easily fixed and sealed to a wall using silicone adhesive or similar. They come finished and wrapped over on all edges, the corners are not welded but can be for a small additional charge.

They come in a variety of lengths, should you require an alternative size or thickness please email sales@mpm-eng.co.uk for a quotation. All prices shown on these standard worktops are inclusive of VAT and delivery.

Storage of Copper worktops and upstands:

- Prior to installation, the items must be stored flat.

- Items must be stored at normal room temperature and humidity.

- The plastic coating protecting the copper must be undamaged and left intact until installation is completed.

- We recommend that the plastic coating protecting the Copper must be left intact until installation is completed.

Fitting Copper worktops and upstands:

- Items should only be fitted in areas that experience normal household ranges of temperature and humidity.

- Care should be taken in newly built areas to ensure a stable atmosphere. All windows/doors should be in place, plasterwork fully dry and major works completed prior to installation.

Cleaning and care for Copper worktops and upstands:

- Chlorides such as bleach or common salt and acids of any kind can damage all grades of copper surfaces. If a spillage occurs rinse immediately and thoroughly with plenty of fresh water and then dry with a soft cloth.

- To maintain the best appearance of your Copper worktops, only use warm water and a mild detergent ensuring that the surface is rinsed thoroughly and then dried with a soft cloth. Copper will oxidise over time and will discolour by varying degrees. Most people accept this will happen and like the different patinas that appear (ring marks discolouration etc.). You can always bring copper back to a flat finish by gently rubbing over the surface with wire wool or similar specific copper cleaning products.

Discolouration:

Copper in its natural form has a dull finish and will age and change colour over time once it has been exposed to air. If the product has been welded and cleaned, this area could appear brighter and slightly different to the original copper sheet. This will also age and change colour over time along with the rest of the worktop.

Marking:

Although the sheets come directly from the mill, copper by its very nature is a relatively soft material and may have some minor marks, scratches and dents in it from new. Where a welding process has taken place, there could be some minor pitting. This is quite normal and a natural by-product of the welding process and will blend in over time.

Never place hot pans that have come off the hob/stove directly onto the worktop as this has the potential of breaking the bond between the worktop and the substrate. Always place hot objects onto a board or trivet to protect the work surface.

IMPORTANT: Care should be taken when handling and installing these products. For your safety, we recommend that hands are protected from unfinished edges and corners.